I’m using 6mm x 60mm for the single thickness assemblies and 6mm x 80mm for the double thickness ones.

I’m using 6mm x 60mm for the single thickness assemblies and 6mm x 80mm for the double thickness ones.

After making the first layer of each side wall, the second layer went quickly because we just used the first layer as the template and cut it with the flush trim router. Then we ran a 1/2″ round-over bit along the edges of both sides (except the edges that attach to other walls). The left side wall just needs some channels routed to run the wiring and hold the 12 volt transformer. Next we’ll drill attachment holes and trial fit the sides to the back wall. Then Barb can start priming those while I work on the front wall. I’m saving the hardest part (the eight sided towers) for last.

Not much progress for the last two weeks but that doesn’t mean we haven’t been busy. We had Holly for two weeks and I spent as much time with her as I could. The best two weeks of my life.

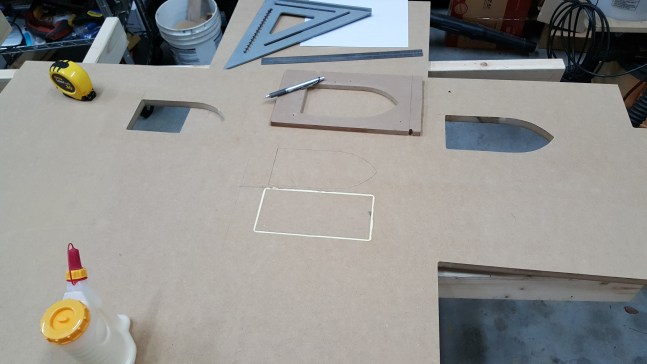

The last thing I did was cut a window in the wrong place so I made a patch for the hole.

Tonight I made a circle cutting jig for my router and cut the archway for one of the sidewall doors. We finished cutting and routing the doorway and called it a night. (The arch came out really nice)

This is a dust cyclone. This one has the brand name Dust Deputy. MDF makes lots of really fine dust that clogs my shop vac filter quickly. This device traps 99% of the dust before it gets to the filter.

To collect the dust, you have to remember to turn the vacuum on each time. With this device, you plug in the vacuum and the power tool you are using. When you start your saw or whatever the vac starts automatically and when you turn the saw off the vac runs for 7 seconds more to clear the hose and then automatically shuts off.

This where the power cord that plugs into the wall will run.

We filled the gaps and screw holes with wood filler.

I rounded the turret edges with a 1/2″ roundover bit.

We attached this to help with handling the heavy panels. Barb and I were having a really hard time dealing with the panel once we made it double thickness. I brought a scale to work today and weighted it. 184 POUNDS!!! No wonder we were having trouble lifting it. With the hinged swing attached to the table we were able to tilt it down and then balance it on caster carts, roll it into the shop and spin it around, then tilt it back onto the table to work on the other side.

UPDATE I just found a picture of the back wall that shows that it is only a double layer along the top turret area and at the four spots where the side walls attach. Building that way has two advantages. 1) It will reduce the weight to about 115 lbs. instead of 184 lbs. and 2) It would require one less 4 x 8 sheet of MDF.